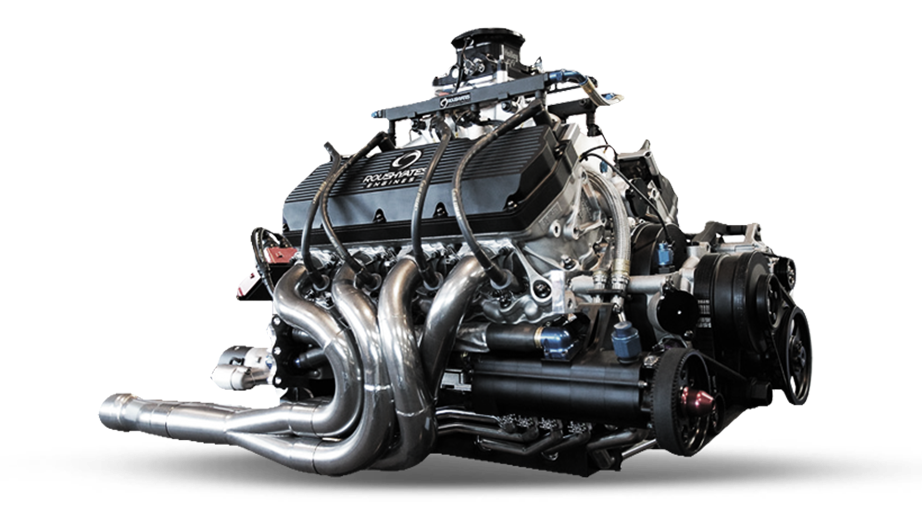

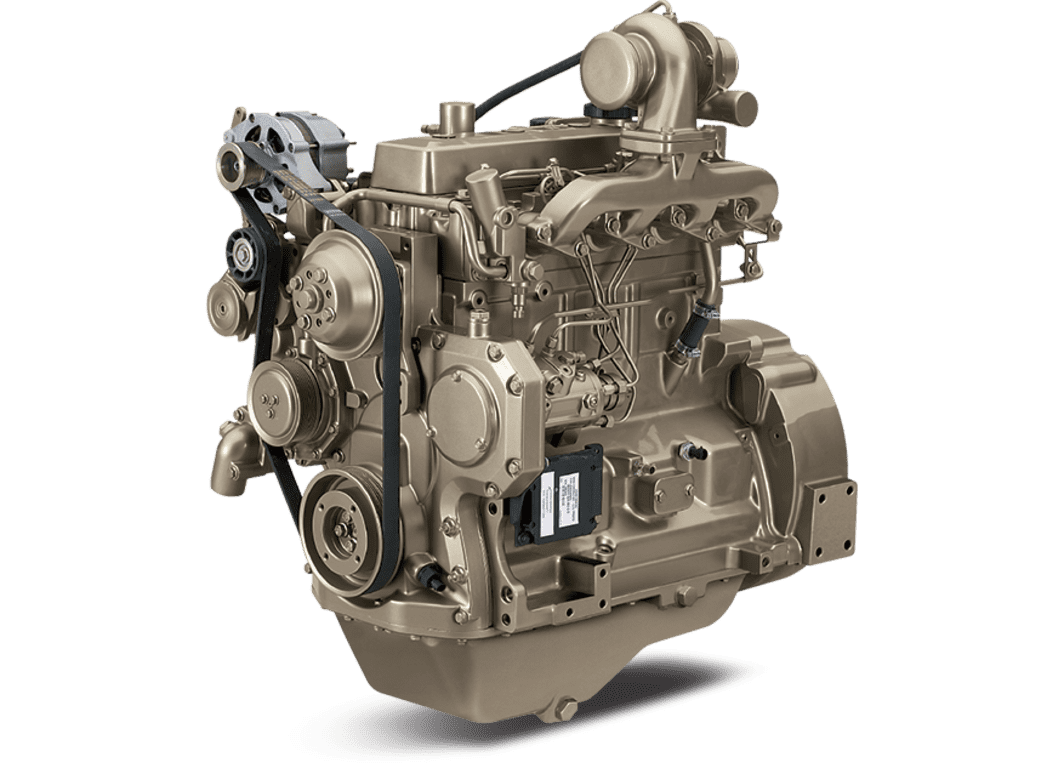

engine dyno

break-in

Engine Break-in

Before a new-build is set up on the engine dyno, it goes through a series of procedures to prepare it for break-in. Break in is the most critical time in the engine’s life, so we take great care to ensure it is done correctly. To protect your engine during this process, we’ll continually monitor your engine temperature, oil pressure, exhaust gas temperature, and air-fuel ratio.

engine dyno Break-in

1. Transportation

2. Inspection

3. Lubricant

Once the break-in oil is added, we prime until the oil reaches the level of the rocker arms.

4. Starting the Engine

Next, we dial-in to the true timing mark while slightly retarding it to avoid any potential for knock.

5. Warm-up

If the engine is fitted with new flat tappet hydraulic cams, we run the engine between 2,000 and 2,500 rpm, with no load, for 30 minutes to ensure proper cam lobe break-in. If new camshafts have not been fitted or if the engine is fitted with roller cams we’ll instead run the engine at high-idle until the cooling fan cycles on.

6. Seating the Rings

Next, we follow the same procedure for 10-15 cycles but run the engine up to 5,500 rpm.

For the last break-in pulls, starting with light throttle, we’ll progress to five WOT cycles, allowing the internal engine temperature to stabilize between cycles.

7. Finishing

The final step in the procedure is to adjust the valve lash.

8. Tuning

During the tuning pulls we’ll run the engine hard to produce the pressure required to further seat the piston rings and to ensure uniform wear.

After the final pull, we’ll change the oil and filter again and prepare your engine for transportation.

NOTE

share this page

Marc Chartrand

Marc Chartrand